Enforcement Activity

PHMSA’s Pipeline Safety Enforcement Program is a key component of our oversight mission.

The Pipeline Safety Enforcement Program is designed to monitor and enforce compliance with pipeline safety regulations and confirm operators are meeting PHMSA expectations for safe, reliable, and environmentally sound operation of their facilities.

On this website PHMSA offers a variety of reports and records detailing its enforcement activity involving pipeline operators. These reports and records are offered on both nationwide and operator-specific bases and includes the following:

How to Access Files

To load the data file into MS Excel:

- Download “Enforcement Cases Initiated from 2002” under the “Enforcement Cases Initiated from 2002”.

- Open Excel and click “Open”. This will start the “Open” dialog box.

- Change file type to “All Files”.

- Select the data TXT file and click “Open”.

- Excel will start the Text Import Wizard and display the first dialog.

- Under “Choose the file type that best describes your data:”, select “Delimited”, click next.

- In the second dialog, select “Tab” under “Delimiters”.

- Uncheck “Treat consecutive delimiters as one”, click next.

- In the third dialog set “Column data format” to “General”.

- Click “Finish”; to import the data.

Enforcement Cases Initiated from 2002 (data as of 05/01/2025)

Enforcement Data Dictionary (link will open in a new browser tab or window)

These pages include archived documents for older enforcement cases that were pursued within each of PHMSA’s Office of Pipeline Safety regions. Unlike the records contained on the Enforcement Actions (2002 — Present) page, these documents have not been checked for accuracy or completeness due to differing recordkeeping practices and procedures that were in place at the time. Further, these pages do not represent a complete listing of all of the enforcement cases initiated during this time period. To see the document(s) archived for a particular case, select the case of interest in the “Case Number” column.

PHMSA monitors compliance through field inspections of facilities and construction projects; programmatic inspections of operator management systems, procedures, and processes; incident investigations; and through direct dialogue with operator management. To facilitate compliance, PHMSA clarifies its regulatory expectations with published inspection forms and protocols; rule interpretations; guidance manuals and advisory notices; FAQs; posting of final orders on its website; and public meetings and workshops. Finally, PHMSA has available a full range of enforcement mechanisms to require that operators take appropriate and timely corrective actions for violations, and that they take preventive measures to preclude future failures or non-compliant operation of their pipelines.

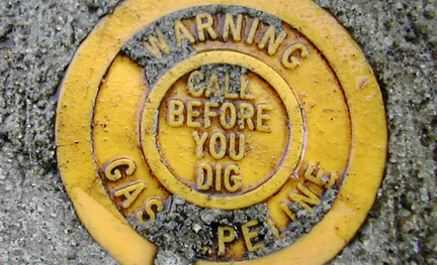

To find out if a gas transmission pipeline or hazardous liquid trunkline is located near you, visit the National Pipeline Mapping System and search by your county or zip code.