Operator compliance with pipeline safety regulations that establish minimal federal safety standards is critical to preventing pipeline accidents. Ensuring compliance involves regular inspections of pipeline operator programs and facilities and, when compliance violations are identified, the application of appropriate administrative, civil, or criminal remedies.

Federal and state pipeline inspectors conduct these compliance inspections and also conduct accident investigations and respond to public inquiries concerning pipeline operations.

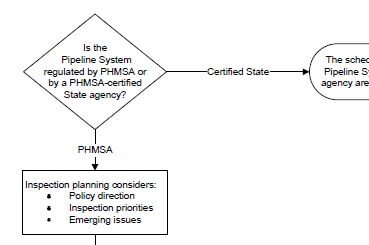

Federal Inspections: PHMSA’s Office of Pipeline Safety (OPS) is responsible for oversight of interstate pipeline systems (pipeline systems that cross state boundaries), as well as intrastate pipeline systems (pipeline systems wholly within a state’s borders), except in states which are certified by PHMSA as a state partner. (See "State Inspections" below.) PHMSA’s pipeline inspectors primarily operate out of regional offices in Trenton, NJ; Atlanta, GA; Kansas City, MO; Houston, TX; and Denver, CO. These inspectors implement a comprehensive inspection and enforcement program to verify that pipeline operators fully comply with PHMSA’s pipeline safety regulations. These offices, along with PHMSA’s headquarters in Washington, D.C., are also responsible for the investigation of pipeline accidents on pipelines they oversee.

State Inspections: While the federal government is primarily responsible for developing, issuing, and enforcing pipeline safety regulations, the pipeline safety statutes provide for states to assume intrastate regulatory, inspection, and enforcement responsibilities under an annual certification. If a state has a pipeline safety program certified by PHMSA, that state agency is responsible for conducting inspections and accident investigations on intrastate pipelines that lie entirely within that state's borders. Most gas distribution pipeline systems and some intrastate systems fall under this state jurisdiction. As a result, the majority of total pipeline inspections conducted across the nation are carried out by state inspectors who work for state agencies, while a majority of pipeline inspections conducted on pipelines other than gas distribution pipelines are carried out by PHMSA’s federal inspectors.

PHMSA issues state certifications for pipeline safety oversight separately for gas pipelines and for hazardous liquid pipelines, with different levels of certification possible. See Federal and State Authorities for more information.

Click here for an explanation of various Regulated Entities and Facilities subject to pipeline safety regulations.

Historical Perspective: PHMSA’s pipeline safety regulations were originally established in the early 1970s and were based primarily on industry consensus standards in effect at the time. However, PHMSA has supplemented and updated these regulations numerous times throughout the years through the addition of new regulations and regulatory programs. Along with these changes, PHMSA’s inspection program has evolved over the years as well. PHMSA’s inspection program consists of both system-wide program inspections and site-specific field inspections. System-wide program inspections cover an operator’s system-wide processes and procedures, while site-specific field inspections cover more localized procedures and the field implementation of procedures and processes at various field locations. When PHMSA promulgates a significant new regulatory program (like those for integrity management and operator qualification in the early 2000’s), PHMSA typically accompanies these new regulatory programs with a supplemental inspection program that is conducted separately from their basic program and field inspections as a means to ensure that the new requirements are fully understood and fully complied with. As operators’ implementation of these new regulatory programs mature, these inspections are incorporated within PHMSA’s other, ongoing inspections.

Beginning around 2008, PHMSA began introducing an integrated inspection process which utilizes risk and safety data and information to better focus its inspection resources on higher risk facilities and areas of concern. By using data and information about a specific operator and pipeline system, an inspector can custom-build a list of regulatory requirements that will have the highest priority during an inspection. This data-driven process allows PHMSA to focus inspection resources on regulatory provisions which address the greatest identified risks and concerns. PHMSA still uses non-integrated inspections (such as New Construction Inspections, Control Room Management Inspections, Integrity Management Inspections, Operator Qualification Inspections, and other inspections) on a situational basis, but typically PHMSA now employs the new integrated inspection process to customize their inspections. PHMSA’s pipeline inspection process is depicted in this flowchart.