Research & Development: Strengthening Consensus Standards

R&D Menu

Collaborative research targeting consensus standards will feed new knowledge into the process of keeping standards relevant to their purpose. The PHMSA program is funding this related research to strengthen their scope and to expand their applicability. Significant time and resources are consumed reaching consensus on a research strategy at R&D forums and other stakeholder events. Given this, itís imperative that knowledge from the research is transferred to sustain Standards Developing Organizations (SDOs). PHMSA is working diligently to measuring the research benefit of projects addressing standards while providing knowledge transfer to the standards-development process.

To ensure success with this research program objective, PHMSA and the Pipeline Standards-Developing Organizations Coordinating Council (PSDOCC) entered a Memorandum of Agreement (MOA). The MOA is improving cooperation and coordination between "the Parties" to simplify a more effective and efficient integration of pipeline safety research and development results into the development and revision of voluntary consensus technical standards. The systematic process described in the MOA is critical to ensure knowledge from pipeline safety research is transferred to end users.

In 2007 PHMSA issued the first data call to relevant SDOs about how the collaborative research with industry is impacting their standards. This was the first time PHMSA contacted SDOs in this capacity and in line with actions described in the MOA. It will take multiple iterations working with SDOs to standardize their responses to these data calls so the public can understand the true impact.

PHMSA will contact relevant SDOs annually and capture the current status or final impact of that research addressing their standards. Many SDOs revise standards on a three or five year frequency so it could take multiple years to register the final and desired impact "Standard Revised." In addition, PHMSA and the PSDOCC must work harder to share the research with the SDO committees to ensure the results are factored when revising consensus standards.

The goal through coordination is to refine future SDO responses down to the following three:

- The research results will be forwarded to committee officers for use in revising the standard.

(Meaning no word yet on the impact but the committee should address this when reconvening) - The research was used in part to revise this standard.

(Meaning the committee reviewed the research results and it was used in part to revise the standard) - The research was not used to revise this standard.

(Meaning the committee reviewed the research results and it was decided that it would not be used to revise the standard)

The following section documents the program success in strengthening consensus standards.

Research Relevance with Standards Developing Organizations

| Objective | Standards Addressed by Projects | Projects Addressing StandardsA | PHMSA |

|---|---|---|---|

| Strengthening Standards | 43 | 110 | $51.55M |

- One project may impact multiple standards; thus the count shown here can and will be different from more-detailed counts.

| No. | Organization Name | Standards Addressed by Projects |

Projects Addressing StandardsA |

PHMSAA |

|---|---|---|---|---|

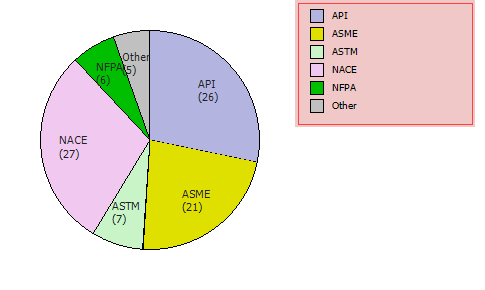

| 1. | American Society of Mechanical Engineers (ASME) | 7 | 21 | $ 9.32M |

| 2. | American Petroleum Institute (API) | 10 | 26 | $11.41M |

| 3. | NACE International (NACE) | 14 | 27 | $ 6.37M |

| 4. | National Fire Protection Association (NFPA) | 1 | 6 | $ 2.48M |

| 5. | American Society for Testing and Materials (ASTM) | 6 | 7 | $ 3.39M |

| 6. | Det Norske Veritas (DNV) | 1 | 1 | $ 0.17M |

| 7. | American Welding Society (AWS) | 3 | 3 | $ 1.36M |

| 8. | Society for Protective Coatings (SSPC) | 1 | 1 | $ 0.14M |

- Some projects impact multiple standards sometime from multiple SDOs; thus the counts and funding values shown here includes some double counting (sums to more than 100%), and has differences from more-detailed values shown further below.

| No. | Organization Name | % AddressedA, B |

% RevisedC |

Standard Relevance CountD |

Impact Meter |

|---|---|---|---|---|---|

| 1. | American Petroleum Institute (API) | 28% | 30% | 26 | |

| 2. | American Society of Mechanical Engineers (ASME) | 22% | 0% | 21 | |

| 3. | American Society for Testing and Materials (ASTM) | 7% | 0% | 7 | |

| 4. | American Welding Society (AWS) | 3% | 0% | 3 | |

| 5. | Det Norske Veritas (DNV) | 1% | 0% | 1 | |

| 6. | NACE International (NACE) | 29% | 7% | 27 | |

| 7. | National Fire Protection Association (NFPA) | 6% | 0% | 6 | |

| 8. | Society for Protective Coatings (SSPC) | 1% | 0% | 1 |

- The number of projects addressing an SDO divided by the number of projects the PHMSA program has addressing all consensus standards.

- These percentages may not total 100% since some projects are targeting the development of new standards yet directed by an SDO.

- The number of projects revising standards issued by an SDO divided by the number of projects addressing that same SDO.

- The total number of PHMSA projects targeting consensus standards issued by an SDO.

| Seq | Standard # | Standard Title | Projects Addressing Standard |

Projects Used to Impact Standard |

Identified Impacting Projects | PHMSA | SDO File |

|---|---|---|---|---|---|---|---|

| American Petroleum Institute (API) | |||||||

| 1. | API 939-D | Technical Report - Stress Corrosion Cracking of Carbon Steel in Fuel Grade Ethanol: Review and Survey, Second Edition | 2 | $ 0.25M | |||

| 2. | API 939-E | Technical Bulletin - Identification, Repair, and Mitigation of Cracking of Steel Equipment in Fuel Ethanol Service | 2 | $ 0.25M | |||

| 3. | Publ 1163 | In-line Inspection Systems Qualification Standard | 1 | $ 0.56M | |||

| 4. | RP 1166 | Excavation Monitoring and Observation | 1 | $ 0.07M | |||

| 5. | RP 1177 | Recommended Practice for Steel Pipeline Construction Quality Management Systems, 1st Edition | 1 | 1 | #504 | $ 0.30M |  |

| 6. | RP 1183 | Assessment and Management of Dents in Pipelines | 5 | 5 | #146 #238 #358 #555 #557 |

$ 4.53M |  |

| 7. | RP 579 | Fitness-for-Service | 2 | $ 0.89M | |||

| 8. | Spec 5L | Specification for Line Pipe | 1 | $ 0.14M | |||

| 9. | Std 1104 | Welding of Pipelines and Related Facilities | 9 | 2 | #128 #133 |

$ 3.87M | /matrix/FilGet.rdm?fil=3646 |

| 10. | TR 939-D | Stress Corrosion Cracking of Carbon Steel in Fuel Grade Ethanol | 2 | $ 0.51M | |||

| American Society of Mechanical Engineers (ASME) | |||||||

| 1. | B31.12 | Hydrogen Piping and Pipelines | 4 | $ 1.55M | |||

| 2. | B31.3 | 2004 Process Piping | 1 | $ 0.14M | |||

| 3. | B31.4 | Pipeline Transportation Systems for Liquid Hydrocarbons and Other Liquids | 4 | $ 1.63M | |||

| 4. | B31.8 | Gas Transmission and Distribution Piping Systems | 7 | $ 4.10M | |||

| 5. | B31.8 BS 7910 | Gas Transmission and Distribution Piping Systems | 1 | $ 0.17M | |||

| 6. | B31.8S | Managing System Integrity of Gas Pipelines | 3 | $ 0.83M | |||

| 7. | B31G/RSTRENG | Manual: Determining Remaining Strength of Corroded Pipelines | 1 | $ 0.87M | |||

| American Society for Testing and Materials (ASTM) | |||||||

| 1. | D-4806 | Specification for Denatured Fuel Ethanol for Blending with Gasolines for Use as Automotive Spark-Ignition Engine Fuel | 2 | $ 0.51M | |||

| 2. | D2513 | Standard Specification for Thermoplastic Gas Pressure Pipe, Tubing, and Fittings | 1 | $ 0.58M | |||

| 3. | D2657 | Standard Practice for Heat Fusion Joining of Polyolefin Pipe and Fittings | 1 | $ 0.58M | |||

| 4. | E1820 | Standard Test Method for Measurement of Fracture Toughness | 1 | $ 0.80M | |||

| 5. | E1961-98(2003)e1 | Standard Practice for Mechanized Ultrasonic Examination of Girth Welds Using Zonal Discrimination with Focused Search Un | 1 | $ 0.35M | |||

| 6. | E2472-06 | Standard Test Method for Determination of Resistance to Stable Crack Extension under Low-Constraint Conditions | 1 | $ 0.55M | |||

| American Welding Society (AWS) | |||||||

| 1. | A5.X | Filler Metal Specifications | 1 | $ 0.60M | |||

| 2. | B4.0 | Standard Methods for Mechanical Testing of Welds | 1 | $ 0.60M | |||

| 3. | D10.12 | Guide for Welding Mild Steel Pipe | 1 | $ 0.14M | |||

| Det Norske Veritas (DNV) | |||||||

| 1. | DNV RP F-101 | Submarine Pipeline Systems, October 2005 | 1 | $ 0.17M | |||

| NACE International (NACE) | |||||||

| 1. | RP 0105-2005 | Liquid-Epoxy Coatings | 1 | $ 0.14M | |||

| 2. | RP 0169 | Control of External Corrosion on Underground or Submerged Metallic Piping Systems | 1 | $ 0.08M | |||

| 3. | RP 0169-2002 | Control of External Corrosion on Underground or Submerged Metallic Piping Systems | 1 | $ 0.45M | |||

| 4. | RP 0178-2003 | Fabrication Details, Surface Finish Requirements, and Proper Design Considerations for Tanks and Vessels to Be Lined for | 1 | $ 0.14M | |||

| 5. | RP 0204-2004 | Stress Corrosion Cracking (SCC) Direct Assessment Methodology | 2 | $ 0.73M | |||

| 6. | RP 0303-2003 | Field-Applied Heat-Shrinkable Sleeves | 1 | $ 0.14M | |||

| 7. | RP 0394-94 | Application, Performance, and Quality Control of Plant-Applied, Fusion-Bonded Epoxy External Pipe Coating | 1 | $ 0.24M | |||

| 8. | RP 0502 | Pipeline External Corrosion Direct Assessment Methodology | 12 | $ 2.95M | |||

| 9. | RP 0694-94 | Commercial Blast Cleaning? | 1 | $ 0.24M | |||

| 10. | SP 0206-2006 | Internal Corrosion Direct Assessment Methodology for Pipelines Carrying Normally Dry Natural Gas (DG-ICDA) | 1 | $ 0.19M | |||

| 11. | SP 0502 | Pipeline External Corrosion Direct Assessment Methodology | 1 | $ 0.25M | |||

| 12. | TG 294 | Above ground testing for coating condition assessment | 1 | $ 0.13M | |||

| 13. | TG 305 | Wet Gas ICDA Standard | 2 | 1 | #177 | $ 0.47M |  |

| 14. | TG 315 | Liquid Petroleum ICDA Standard | 1 | 1 | #167 | $ 0.18M |  |

| National Fire Protection Association (NFPA) | |||||||

| 1. | 59A | Standard for the Production, Storage, and Handling of Liquefied Natural Gas | 6 | $ 2.48M | |||

| Society for Protective Coatings (SSPC) | |||||||

| 1. | SSPC-PA1 | Shop, Field, and Maintenance Painting | 1 | $ 0.14M | |||

| SDO | Projects Addressing Standards |

Project Results Used to Revise a Standard |

|---|---|---|

| Category: Threat Prevention | ||

| American Petroleum Institute (API) | 2 | 1 |

| American Society of Mechanical Engineers (ASME) | 1 | |

| Category Sub-Totals: | 3 | 1 |

| Category: Anomaly Detection | ||

| American Society of Mechanical Engineers (ASME) | 1 | |

| NACE International (NACE) | 19 | 2 |

| Category Sub-Totals: | 20 | 2 |

| Category: Anomaly Characterization | ||

| American Petroleum Institute (API) | 6 | 5 |

| American Society of Mechanical Engineers (ASME) | 2 | |

| NACE International (NACE) | 3 | |

| Category Sub-Totals: | 11 | 5 |

| Category: Anomaly Repair | ||

| American Petroleum Institute (API) | 2 | |

| American Society of Mechanical Engineers (ASME) | 2 | |

| Category Sub-Totals: | 4 | 0 |

| Category: Materials | ||

| American Petroleum Institute (API) | 2 | |

| American Society of Mechanical Engineers (ASME) | 6 | |

| American Society for Testing and Materials (ASTM) | 1 | |

| American Welding Society (AWS) | 1 | |

| Det Norske Veritas (DNV) | 1 | |

| NACE International (NACE) | 5 | |

| Society for Protective Coatings (SSPC) | 1 | |

| Category Sub-Totals: | 17 | 0 |

| Category: Welding | ||

| American Petroleum Institute (API) | 8 | 2 |

| American Society of Mechanical Engineers (ASME) | 6 | |

| American Society for Testing and Materials (ASTM) | 2 | |

| American Welding Society (AWS) | 2 | |

| Category Sub-Totals: | 18 | 2 |

| Category: Joining | ||

| American Society for Testing and Materials (ASTM) | 2 | |

| Category Sub-Totals: | 2 | 0 |

| Category: Alternative Fuels | ||

| American Petroleum Institute (API) | 6 | |

| American Society of Mechanical Engineers (ASME) | 3 | |

| American Society for Testing and Materials (ASTM) | 2 | |

| Category Sub-Totals: | 11 | 0 |

| Category: Liquefied Natural Gas | ||

| National Fire Protection Association (NFPA) | 6 | |

| Category Sub-Totals: | 6 | 0 |

| Grand Totals: | 92 | 10 |

| No. | Project Title | Project StatusA | SDO | Category | Standard No/Title | Confirmed | SDO Notes | File |

|---|---|---|---|---|---|---|---|---|

| Not Determined | ||||||||

| 1. | Pipeline Assessment and Repair Manual | Closed | API | Anomaly Repair | RP 579, "Fitness-For-Service" | |||

| 2. | Improved In-field Welding and Coating Protocols | Closed | API | Materials | Spec 5L, "Specification for Line Pipe" | |||

| 3. | Development of HAZ Hardness Limits for In-Service Welding | Closed | API | Welding | Std 1104, "Welding of Pipelines and Related Facilities" | |||

| 4. | Validation of Assessment Methods for Production Scale Girth Welding of High Strength Pipelines with Multiple Pipe Sources | Closed | API | Welding | Std 1104, "Welding of Pipelines and Related Facilities" | |||

| 5. | Validation of Assessment Methods for Production Scale Girth Welding of High Strength Pipelines with Multiple Pipe Sources | Closed | API | Welding | RP 579, "Fitness-for-Service" | |||

| 6. | Automated Laser Ultrasonic Testing (ALUT) Of Hybrid Laser Arc Welds For Pipeline Construction | Closed | API | Welding | Std 1104, "Welding of Pipelines and Related Facilities" | |||

| 7. | Update of Weld Design, Testing, and Assessment Procedures for High Strength Pipelines | Closed | API | Welding | Std 1104, "Welding of Pipelines and Related Facilities" | |||

| 8. | Development of Optimized Welding Solutions for X100 Linepipe Steel | Closed | API | Welding | Std 1104, "Welding of Pipelines and Related Facilities" | |||

| 9. | Effect of Ethanol Source on Stress Corrosion Cracking of Carbon Steel | Closed | API | Alternative Fuels | TR 939-D, "Stress Corrosion Cracking of Carbon Steel in Fuel Grade Ethanol" | |||

| 10. | Effect of Ethanol Blends and Batching Operations on Stress Corrosion Cracking of Carbon Steel | Closed | API | Alternative Fuels | TR 939-D, "Stress Corrosion Cracking of Carbon Steel in Fuel Grade Ethanol" | |||

| 11. | Monitoring Conditions Leading to SCC/Corrosion of Carbon Steel | Closed | API | Alternative Fuels | API 939-E, "Technical Bulletin - Identification, Repair, and Mitigation of Cracking of Steel Equipment in Fuel Ethanol Service" | |||

| 12. | Monitoring Conditions Leading to SCC/Corrosion of Carbon Steel | Closed | API | Alternative Fuels | API 939-D, "Technical Report - Stress Corrosion Cracking of Carbon Steel in Fuel Grade Ethanol: Review and Survey, Second Edition" | |||

| 13. | Determine the Requirements for Existing Pipeline, Tank and Terminal Systems to Transport Ethanol without Cracking | Closed | API | Alternative Fuels | API 939-D, "Technical Report - Stress Corrosion Cracking of Carbon Steel in Fuel Grade Ethanol: Review and Survey, Second Edition" | |||

| 14. | Determine the Requirements for Existing Pipeline, Tank and Terminal Systems to Transport Ethanol without Cracking | Closed | API | Alternative Fuels | API 939-E, "Technical Bulletin - Identification, Repair, and Mitigation of Cracking of Steel Equipment in Fuel Ethanol Service" | |||

| 15. | Task Order #2: Fatigue Fracture and Crack Arrest in High-Strength Pipeline Steels | Closed | ASME | Materials | B31.8S, "Managing System Integrity of Gas Pipelines" | |||

| 16. | Corrosion Assessment Guidance for Higher Strength Pipelines | Closed | ASME | Materials | B31G/RSTRENG, "Manual: Determining Remaining Strength of Corroded Pipelines" | |||

| 17. | Behavior of Corroded Pipelines Under Cyclic Pressure | Closed | ASME | Materials | B31.8 BS 7910, "Gas Transmission and Distribution Piping Systems" | |||

| 18. | Pipeline Assessment and Repair Manual | Closed | ASME | Anomaly Repair | B31.4, "Pipeline Transportation Systems for Liquid Hydrocarbons and Other Liquids" | |||

| 19. | Pipeline Assessment and Repair Manual | Closed | ASME | Anomaly Repair | B31.8, "Gas Transmission and Distribution Piping Systems" | |||

| 20. | Improved In-field Welding and Coating Protocols | Closed | ASME | Materials | B31.4, "Pipeline Transportation Systems for Liquid Hydrocarbons and Other Liquids" | |||

| 21. | Improved In-field Welding and Coating Protocols | Closed | ASME | Materials | B31.3, "2004 Process Piping" | |||

| 22. | Validation of Assessment Methods for Production Scale Girth Welding of High Strength Pipelines with Multiple Pipe Sources | Closed | ASME | Welding | B31.8, "Gas Transmission and Distribution Piping Systems" | |||

| 23. | Update of Weld Design, Testing, and Assessment Procedures for High Strength Pipelines | Closed | ASME | Welding | B31.8, "Hydrogen Piping and Pipelines" | |||

| 24. | Update of Weld Design, Testing, and Assessment Procedures for High Strength Pipelines | Closed | ASME | Welding | B31.8, "Gas Transmission and Distribution Piping Systems" | |||

| 25. | Update of Weld Design, Testing, and Assessment Procedures for High Strength Pipelines | Closed | ASME | Welding | B31.4, "Pipeline Transportation Systems for Liquid Hydrocarbons and Other Liquids" | |||

| 26. | Development of Optimized Welding Solutions for X100 Linepipe Steel | Closed | ASME | Welding | B31.4, "Pipeline Transportation Systems for Liquid Hydrocarbons and Other Liquids" | |||

| 27. | Development of Optimized Welding Solutions for X100 Linepipe Steel | Closed | ASME | Welding | B31.8, "Gas Transmission and Distribution Piping Systems" | |||

| 28. | Structural Significance of Mechanical Damage | Closed | ASME | Anomaly Characterization | B31.8, "Gas Transmission and Distribution Piping Systems" | |||

| 29. | Pipeline Segment-Specific External Corrosion Rate Estimation to Improve Reassessment Interval Accuracy | Closed | ASME | Anomaly Detection | B31.8S, "Managing System Integrity of Gas Pipelines" | |||

| 30. | Validation for Flaw Acceptance of Mechanical Damage to Low Stress Natural Gas Pipelines | Closed | ASME | Anomaly Characterization | B31.8, "Gas Transmission and Distribution Piping Systems" | |||

| 31. | Performance Evaluation of High-Strength Steel Pipelines for High-Pressure Gaseous Hydrogen Transportation | Closed | ASME | Alternative Fuels | B31.12, "Hydrogen Piping and Pipelines" | |||

| 32. | Cost-Effective Techniques for Weld Property Measurement and Technologies for Improving Weld Hydrogen Embrittlement and Intergranular Stress Corrosion Cracking Resistance for Alternative Fuel Pipelines | Closed | ASME | Alternative Fuels | B31.12, "Hydrogen Piping and Pipelines" | |||

| 33. | Effect of Microstructure of Pipeline Steels on Ductility and Fatigue Properties in High Pressure Hydrogen Atmosphere | Cancelled | ASME | Alternative Fuels | B31.12, "Hydrogen Piping and Pipelines" | |||

| 34. | The Effect of Pressurized Hydrogen Gas on the Fatigue Properties of the Heat-Affected Zones in X52 and X70 Pipelines | Closed | ASME | Materials | B31.12, "Hydrogen Piping and Pipelines" | |||

| 35. | Improved Inspection and Assessment Methods for Pipeline Girth Welds and Repair Welds | Closed | ASTM | Welding | E1961-98(2003)e1, "Standard Practice for Mechanized Ultrasonic Examination of Girth Welds Using Zonal Discrimination with Focused Search Un" | |||

| 36. | Task Order #2: Fatigue Fracture and Crack Arrest in High-Strength Pipeline Steels | Closed | ASTM | Materials | E2472-06, "Standard Test Method for Determination of Resistance to Stable Crack Extension under Low-Constraint Conditions" | |||

| 37. | Butt Fusion Joint Integrity and Evaluation of NDE Technologies | Closed | ASTM | Joining | D2657, "Standard Practice for Heat Fusion Joining of Polyolefin Pipe and Fittings" | |||

| 38. | Butt Fusion Joint Integrity and Evaluation of NDE Technologies | Closed | ASTM | Joining | D2513, "Standard Specification for Thermoplastic Gas Pressure Pipe, Tubing, and Fittings" | |||

| 39. | Update of Weld Design, Testing, and Assessment Procedures for High Strength Pipelines | Closed | ASTM | Welding | E1820, "Standard Test Method for Measurement of Fracture Toughness" | |||

| 40. | Effect of Ethanol Source on Stress Corrosion Cracking of Carbon Steel | Closed | ASTM | Alternative Fuels | D-4806, "Specification for Denatured Fuel Ethanol for Blending with Gasolines for Use as Automotive Spark-Ignition Engine Fuel" | |||

| 41. | Effect of Ethanol Blends and Batching Operations on Stress Corrosion Cracking of Carbon Steel | Closed | ASTM | Alternative Fuels | D-4806, "Specification for Denatured Fuel Ethanol for Blending with Gasolines for Use as Automotive Spark-Ignition Engine Fuel" | |||

| 42. | Improved In-field Welding and Coating Protocols | Closed | AWS | Materials | D10.12, "Guide for Welding Mild Steel Pipe" | |||

| 43. | Development of Optimized Welding Solutions for X100 Linepipe Steel | Closed | AWS | Welding | B4.0, "Standard Methods for Mechanical Testing of Welds" | |||

| 44. | Development of Optimized Welding Solutions for X100 Linepipe Steel | Closed | AWS | Welding | A5.X, "Filler Metal Specifications" | |||

| 45. | Behavior of Corroded Pipelines Under Cyclic Pressure | Closed | DNV | Materials | DNV RP F-101, "Submarine Pipeline Systems, October 2005" | |||

| 46. | Task Order #1: External Corrosion of Line Pipe Steels | Closed | NACE | Anomaly Detection | RP 0169-2002, "Control of External Corrosion on Underground or Submerged Metallic Piping Systems" | 10/30/2007 | ||

| 47. | Task Order #1: External Corrosion of Line Pipe Steels | Closed | NACE | Anomaly Detection | RP 0502, "Pipeline External Corrosion Direct Assessment Methodology" | 10/30/2007 | ||

| 48. | Model Modules to Assist Assessing and Controlling Stress Corrosion Cracking (SCC) | Closed | NACE | Anomaly Characterization | RP 0204-2004, "Stress Corrosion Cracking (SCC) Direct Assessment Methodology" | 10/30/2007 | ||

| 49. | Internal Corrosion Direct Assessment Detection of Water | Closed | NACE | Anomaly Detection | TG 305, "Wet Gas ICDA Standard" | 10/30/2007 | ||

| 50. | Guidelines for Interpretation of Close Interval Surveys for ECDA | Closed | NACE | Anomaly Detection | RP 0502, "Pipeline External Corrosion Direct Assessment Methodology" | 10/30/2007 | ||

| 51. | Demonstration of ECDA Applicability and Reliability for Demanding Situations | Closed | NACE | Anomaly Detection | RP 0502, "Pipeline External Corrosion Direct Assessment Methodology" | 10/30/2007 | ||

| 52. | ECDA for Unique Threats to Underground Pipelines | Closed | NACE | Anomaly Detection | RP 0502, "Pipeline External Corrosion Direct Assessment Methodology" | 10/30/2007 | ||

| 53. | Guidelines for the Identification of SCC Sites and the Estimation of Re-Inspection Intervals for SCCDA | Closed | NACE | Anomaly Detection | RP 0204-2004, "Stress Corrosion Cracking (SCC) Direct Assessment Methodology" | 10/30/2007 | ||

| 54. | Improved In-field Welding and Coating Protocols | Closed | NACE | Materials | RP 0303-2003, "Field-Applied Heat-Shrinkable Sleeves" | 10/30/2007 | ||

| 55. | Improved In-field Welding and Coating Protocols | Closed | NACE | Materials | RP 0105-2005, "Liquid-Epoxy Coatings" | 10/30/2007 | ||

| 56. | Improved In-field Welding and Coating Protocols | Closed | NACE | Materials | RP 0178-2003, "Fabrication Details, Surface Finish Requirements, and Proper Design Considerations for Tanks and Vessels to Be Lined for" | 10/30/2007 | ||

| 57. | Phase Sensitive Methods to Detect Cathodic Disbondment | Closed | NACE | Anomaly Detection | RP 0502, "Pipeline External Corrosion Direct Assessment Methodology" | 10/30/2007 | ||

| 58. | Effect of Surface Preparation on Residual Stress in Multi-layer and Other Pipeline Coatings | Closed | NACE | Materials | RP 0394-94, "Application, Performance, and Quality Control of Plant-Applied, Fusion-Bonded Epoxy External Pipe Coating" | 10/30/2007 | ||

| 59. | Effect of Surface Preparation on Residual Stress in Multi-layer and Other Pipeline Coatings | Closed | NACE | Materials | RP 0694-94, "Commercial Blast Cleaning?" | |||

| 60. | External Corrosion Direct Assessment of Cased Pipes | Closed | NACE | Anomaly Detection | RP 0502, "Pipeline External Corrosion Direct Assessment Methodology" | |||

| 61. | Severity Ranking of ECDA Indirect Inspection Indications | Closed | NACE | Anomaly Detection | RP 0502, "Pipeline External Corrosion Direct Assessment Methodology" | |||

| 62. | External Corrosion Direct Assessment - Potential Measurements on Paved Areas | Closed | NACE | Anomaly Detection | RP 0502, "Pipeline External Corrosion Direct Assessment Methodology" | |||

| 63. | Pipeline Segment-Specific External Corrosion Rate Estimation to Improve Reassessment Interval Accuracy | Closed | NACE | Anomaly Detection | RP 0502, "Pipeline External Corrosion Direct Assessment Methodology" | |||

| 64. | Validation of External Corrosion Growth-Rate Using Polarization Resistance and Soil Properties | Closed | NACE | Anomaly Characterization | SP 0502, "Pipeline External Corrosion Direct Assessment Methodology" | |||

| 65. | Consistency Review of Methodologies for Quantitative Risk Assessment | Closed | NFPA | Liquefied Natural Gas | 59A, "Standard for the Production, Storage, and Handling of Liquefied Natural Gas" | |||

| 66. | Performance Gap Comparison of Process Safety Management Consensus Standards and Regulatory Requirements for LNG Facilities | Closed | NFPA | Liquefied Natural Gas | 59A, "Standard for the Production, Storage, and Handling of Liquefied Natural Gas" | |||

| 67. | Improved In-field Welding and Coating Protocols | Closed | SSPC | Materials | SSPC-PA1, "Shop, Field, and Maintenance Painting" | |||

| Out For Revision | ||||||||

| 68. | Effectiveness of Prevention Methods for Excavation Damage | Closed | API | Threat Prevention | RP 1166, "Excavation Monitoring and Observation" | 09/28/2007 | Forwarded to committee officers for use in revising standard. |

|

| 69. | Pipeline Assessment and Repair Manual | Closed | API | Anomaly Repair | Std 1104, "Welding of Pipelines and Related Facilities" | 09/28/2007 | Forwarded to committee officers for use in revising standard. |

|

| 70. | Characterization of Stress Corrosion Cracking Using Laser Ultrasonics | Closed | API | Anomaly Characterization | Publ 1163, "In-line Inspection Systems Qualification Standard" | 09/28/2007 | Forwarded to committee officers for use in revising standard. | |

| 71. | Improved In-field Welding and Coating Protocols | Closed | API | Materials | Std 1104, "Welding of Pipelines and Related Facilities" | 09/28/2007 | Forwarded to committee officers for use in revising standard. | |

| 72. | Effectiveness of Prevention Methods for Excavation Damage | Closed | ASME | Threat Prevention | B31.8S, "Managing System Integrity of Gas Pipelines" | 09/13/2007 | Forwarded to committee officers for use in revising standard. | |

| 73. | Improvements to the External Corrosion Direct Assessment Methodology by Incorporating Soils Data | Closed | NACE | Anomaly Detection | RP 0502, "Pipeline External Corrosion Direct Assessment Methodology" | 10/30/2007 | Forwarded to committee officers for use in revising standard. | |

| 74. | Internal Corrosion Direct Assessment (ICDA) of Gas Transmission, Gathering, and Storage Systems | Closed | NACE | Anomaly Detection | SP 0206-2006, "Internal Corrosion Direct Assessment Methodology for Pipelines Carrying Normally Dry Natural Gas (DG-ICDA)" | 10/30/2007 | Forwarded to committee officers for use in revising standard. |

|

| 75. | High CP Potential Effects on Pipelines | Closed | NACE | Anomaly Characterization | RP 0169, "Control of External Corrosion on Underground or Submerged Metallic Piping Systems" | 10/30/2007 | Forwarded to committee officers for use in revising standard. |

|

| 76. | Determining Integrity Reassessment Intervals Through Corrosion Rate Modeling And Monitoring | Closed | NACE | Anomaly Detection | RP 0502, "External Corrosion Direct Assessment" | 10/30/2007 | Forwarded to committee officers for use in revising standard. |

|

| 77. | Applying External Corrosion Direct Assessment (ECDA) to Difficult to Inspect Areas | Closed | NACE | Anomaly Detection | RP 0502, "Pipeline External Corrosion Direct Assessment Methodology" | 10/30/2007 | Forwarded to committee officers for use in revising standard. |

|

| 78. | Evaluation and Validation of Aboveground Techniques for Coating Condition Assessment | Closed | NACE | Anomaly Detection | TG 294, "Above ground testing for coating condition assessment" | 10/30/2007 | Forwarded to committee officers for use in revising standard. |

|

| 79. | Modeling and Assessing a Spectrum of Accidental Fires and Risks in a LNG Facility | Closed | NFPA | Liquefied Natural Gas | 59A, "Standard for the Production, Storage, and Handling of Liquefied Natural Gas (LNG)" | 04/28/2008 | Forwarded to committee officers for use in revising standard. | |

| Project Active/Pending | ||||||||

| 80. | Evaluation of the Efficacy and Treatment of Hazard Mitigation Measures for LNG Facilities | Closed | NFPA | Liquefied Natural Gas | 59A, "Standard for the Production, Storage, and Handling of Liquefied Natural Gas" | |||

| 81. | Develop a Risk-Based Approach and Criteria for Hazard Detection Layout | Closed | NFPA | Liquefied Natural Gas | 59A, "Standard for the Production, Storage, and Handling of Liquefied Natural Gas" | |||

| 82. | Develop an Evaluation Protocol for Non-LNG Release Hazards - Modeling | Active | NFPA | Liquefied Natural Gas | 59A, "Standard for the Production, Storage, and Handling of Liquefied Natural Gas" | |||

| Standard Revised | ||||||||

| 83. | A Comprehensive Update in the Evaluation of Pipelines Weld Defects | Closed | API | Welding | Std 1104, "Welding of Pipelines and Related Facilities" | 09/28/2007 | API File... | |

| 84. | Improved Inspection and Assessment Methods for Pipeline Girth Welds and Repair Welds | Closed | API | Welding | Std 1104, "Welding of Pipelines and Related Facilities" | 09/28/2007 | API File... | |

| 85. | Mechanical Damage at Welds | Closed | API | Anomaly Characterization | RP 1183, "Assessment and Management of Dents in Pipelines" | 02/25/2020 | API File... | |

| 86. | Structural Significance of Mechanical Damage | Closed | API | Anomaly Characterization | RP 1183, "Assessment and Management of Dents in Pipelines" | 02/25/2020 | API File... | |

| 87. | Dent Fatigue Life Assessment - Development of Tools for Assessing the Severity and Life of Dent Features | Closed | API | Anomaly Characterization | RP 1183, "Assessment and Management of Dents in Pipelines" | 02/25/2020 | API File... | |

| 88. | Improving Quality Management Systems (QMS) for Pipeline Construction Activities | Closed | API | Threat Prevention | RP 1177, "Recommended Practice for Steel Pipeline Construction Quality Management Systems, 1st Edition" | 01/19/2018 | API File... | |

| 89. | Consolidated Project Full Scale Testing of Interactive Features for Improved Models | Closed | API | Anomaly Characterization | RP 1183, "Assessment and Management of Dents in Pipelines" | 02/25/2020 | API File... | |

| 90. | Improving Models to Consider Complex Loadings, Operational Considerations, and Interactive Threats | Closed | API | Anomaly Characterization | RP 1183, "Assessment and Management of Dents in Pipelines" | 02/25/2020 | API File... | |

| 91. | Development of ICDA for Liquid Petroleum Pipelines | Closed | NACE | Anomaly Detection | TG 315, "Liquid Petroleum ICDA Standard" | 10/30/2007 | NACE File... | |

| 92. | Direct Assessment for Internal Corrosion in the Presence of Wet Gas | Closed | NACE | Anomaly Detection | TG 305, "Wet Gas ICDA Standard" | 10/30/2007 | NACE File... | |

- Project Status and Impact Status: